Hardware Design is a process of planning and creating something physical in nature which forms the basis of electronic systems, devices and products. It is a crucial phase in the Embedded Product development of any electronics or electrical system and involves range of activities, from defining the system's architecture to designing the individual hardware components.

It is a collaborative effort that involves Engineers, Hardware designers, PCB Layout specialists and other professionals working together in brining a system to life, ensuring it meets the performance, reliability and efficiency requirements from the customers.

What are aspects of Hardware Design?

After the requirements are gathered from customers, system architecture is finalized. This is an evolving document which provides the blueprint of the hardware design at a higher level. Primary stages of Hardware design includes Circuit Design, Circuit Simulation, Component Selection, Schematic (SCH) and PCB Library Design, Schematic(SCH) Capture, PCB Layout and Routing, PCB Fabrication, PCB Assembly, Functional Verification and Testing.

Circuit Design and Simulation

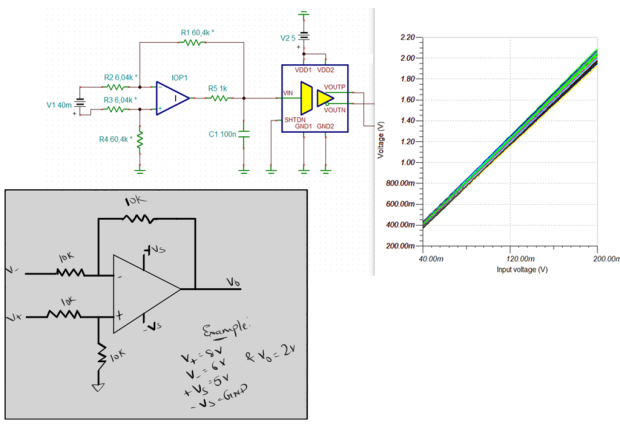

Circuit design is a fundamental aspect of electronics engineering and is essential for creating electronic devices, from simple gadgets to complex systems. We offer our services in Analog Circuit Design, Digital Circuit Design and Mixed Domain circuit Design. Each comes with its unique set of issues and challenges. Our expertise lies in solving various customer issues in all these domains.

The goal of circuit design is to create reliable, efficient, and cost-effective electronic systems that meet specific requirements and perform their intended functions accurately.

Simulation is a technique to model and emulate the behavior of circuit and reinforce the understanding that the designed circuit is working as expected with all the characteristics as per customer requirements. We use varied simulation tools like LTspice®, TINATM by Texas Instruments for Analog simulations and various other softwares for Digital simulations as per the project need.

Schematic & PCB Design

Component Selection is carried out by the team to choose the best components for the design and are also cost-effective with quality. The range of components includes but is not limited to Analog ICs, Voltage Regulator, LDOs, Active components like OPAmps, Digital Components like Micro-Controller, DDRx ICs, FPGA, CPLD, RTC etc.

The goal of component engineering team is to provide the customers with alternate components at the starting of the project thereby helping them in managing the component obsolescence issues.

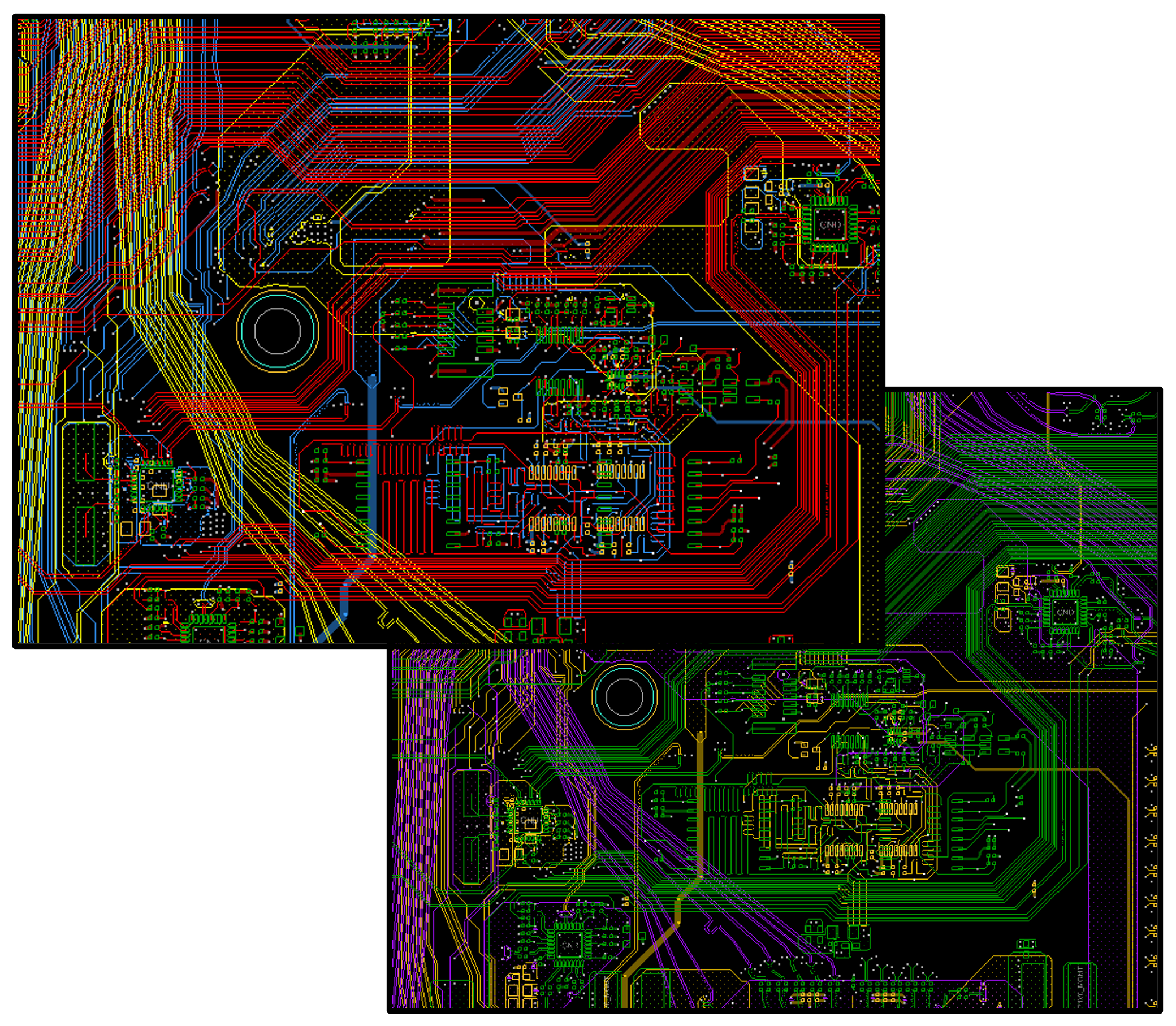

SCH and PCB Library design is tool dependent exercise with same fundamentals where the designer refers to datasheets for the Schematic symbol and PCB Footprint. We uses Altium Designer®, Cadence® tools DE-HDL®, Allegro®, OrCAD® Capture and other market standard CAD tools to deliver to our most advanced customer needs.

Schematic Design or Schematic capture is a process where the hardware design is poured into the design tool. Component selection and Component library design both Schematic and PCB Library is pre-requisite to this stage. Schematic is one of the important documents of the hardware design phase as it contains the Block diagrams, Circuit components and connections. This is an evolving document with multiple revisions to ensure the design is built right and reviewed in time.

PCB Design, short for Printed Circuit board design is where the circuit and schematic are manifested into a physical form. This is a multi faceted exercise which usually starts with deciding the Layer stackup for the project as it plays a crucial role in PCB functionality then followed by Component layout, Routing, EMI-EMC considerations, Fabrication, Assembly and then Functional testing. Each stage needs in-depth analysis and skillful engineers and designer to deliver on our commitments.

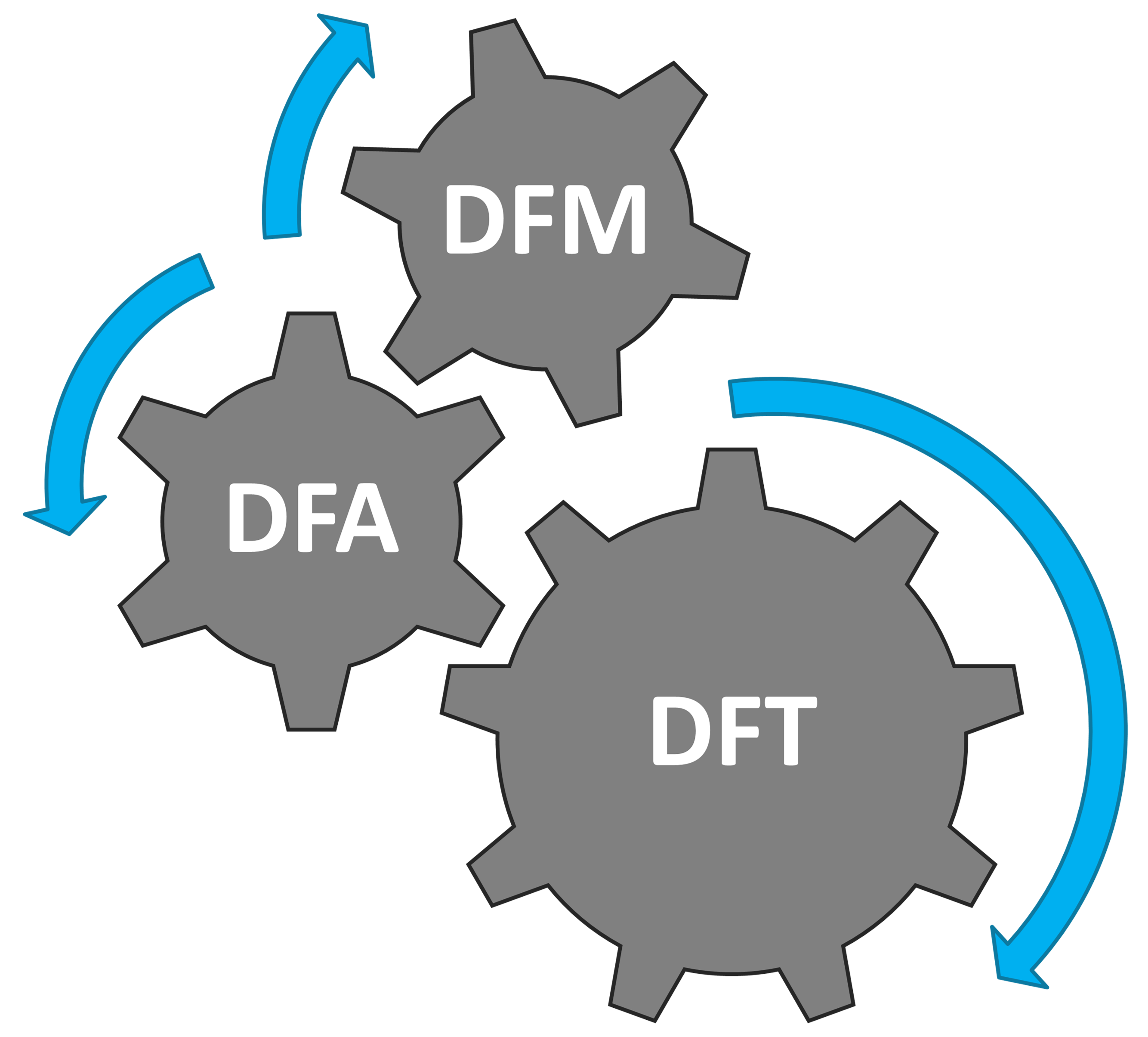

From Stackup to final gerber output at each stage, PCB are designed by keeping DFx rules in mind where 'x' stands for DFT (Design For Testing), DFM (Design For Manufacturing) and DFA (Design For Assembly). These rules reduces the number of re-spins of the board and saves cost and time to market for the product.

Several companies employee Automated Verification systems to thoroughly test their PCBs to ensure their quality are 100% met with each board and each board is tested 100% for its functionality before reaching to customers. This helps immensely in improving the brand value along with scalability and reliability of their products.

We liaison with the third party contract manufacturers, PCB Fab and assembly houses to get the PCBs fabricated and assembled and provide a cost-effective solution tou our customers. You can leverage our skill and expertise to get your ideas to market.

Services offered in Hardware Design

Analog Design, Digital Design, Mixed Domain Design.

Analog Design, Digital Design, Mixed Domain Design. System Architecture and Design.

System Architecture and Design. Circuit Design and Simulation.

Circuit Design and Simulation. Optimized component selection and library creation.

Optimized component selection and library creation.  Schematic Design.

Schematic Design. PCB Layout and Routing.

PCB Layout and Routing.- Multi-Layer PCB Design.

- Stackup Design.

- Component Placement and routing.

- Design for Testing (DFT).

- Design for manufacturing (DFM).

- Design for Assembly (DFA).

EMI-EMC Consultation.

EMI-EMC Consultation. PCB Fabrication and Assembly.

PCB Fabrication and Assembly. Functional testing and Verification.

Functional testing and Verification.